Informação básica

| Modelo Nº. | primavera-azul |

| Nível de Carga | Carga média |

| se deve personalizar | Customizável |

| Contagem de uso | 1 milhão de vezes+ |

| Transporte | DHL,FedEx,UPS,TNT ou por mar |

| Endereço de produção | Wenzhou, Zhejiang, China |

| Prazo de entrega | Estoques agora (ou 8-12 dias) |

| Pacote de transporte | Sacos de plástico internos, caixas externas ou caixas de madeira, |

| Especificação | Peças padrão e personalizáveis |

| Marca comercial | cang |

| Origem | Wenzhou |

| Capacidade de produção | 50000 peças/ano |

Descrição do produto

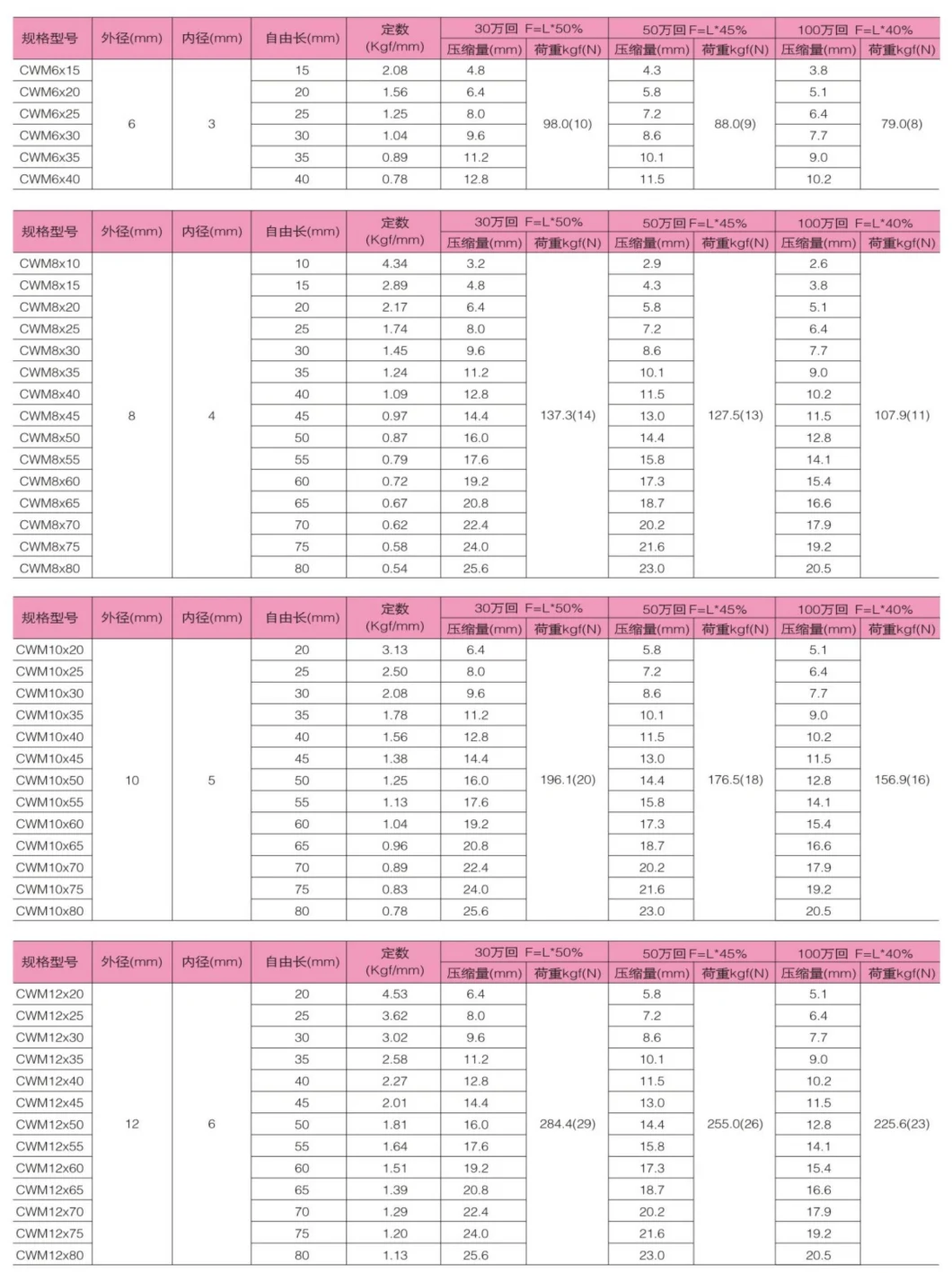

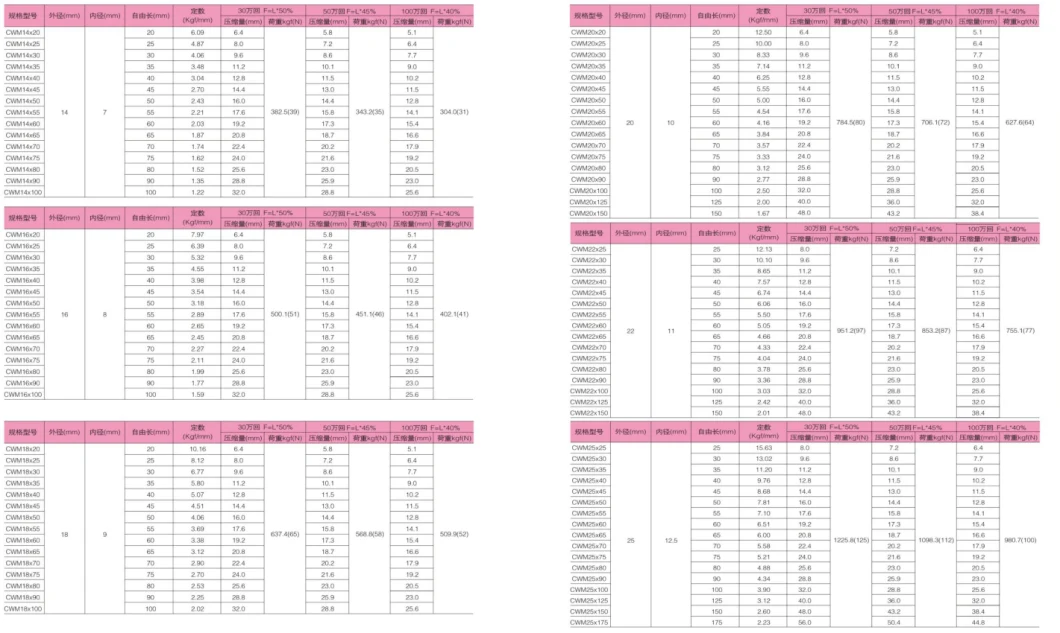

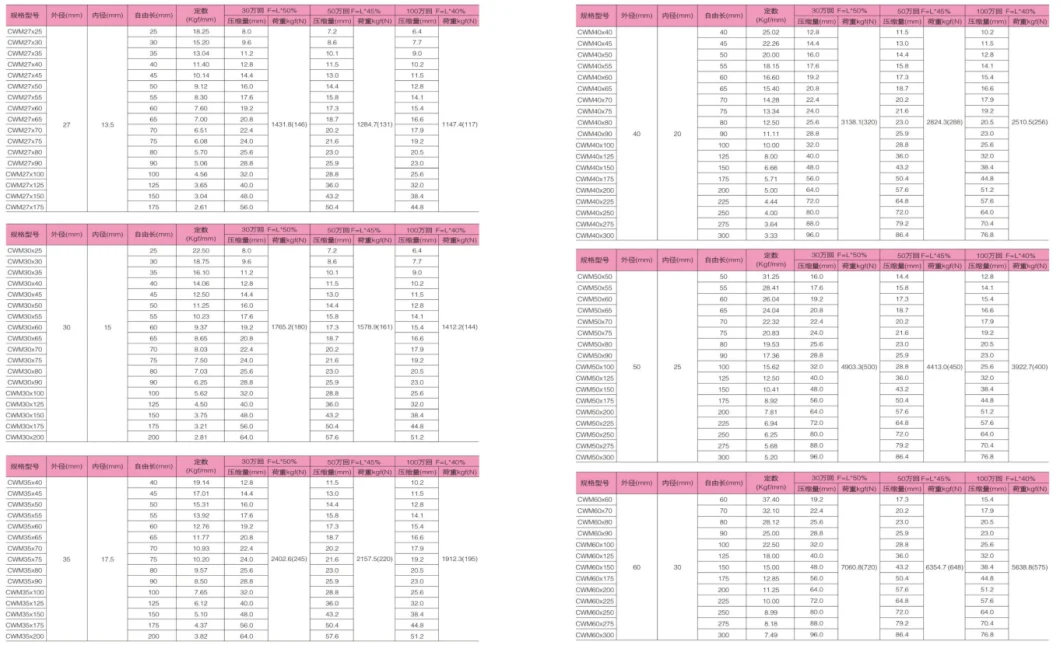

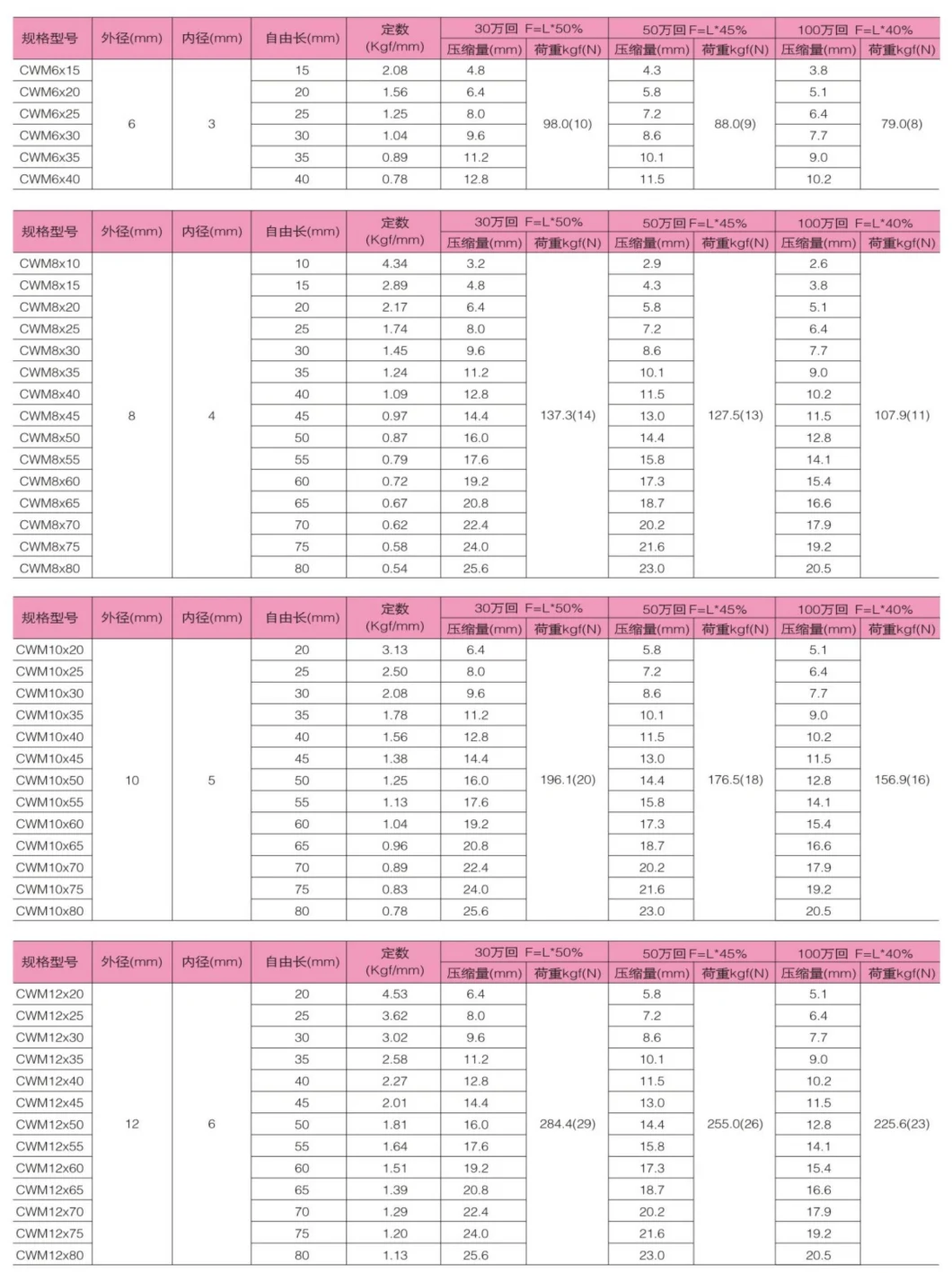

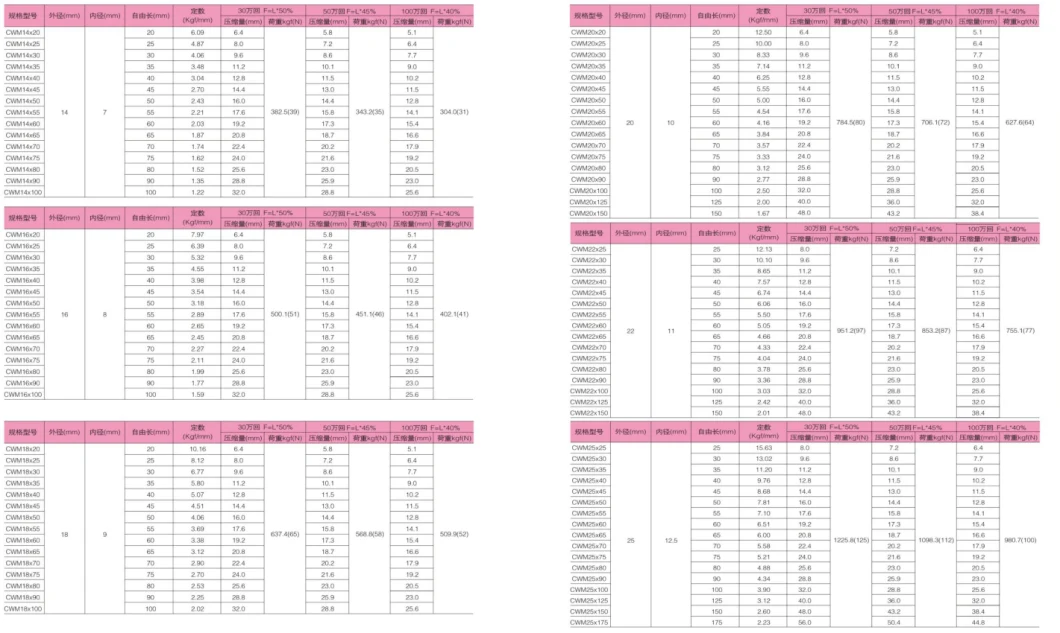

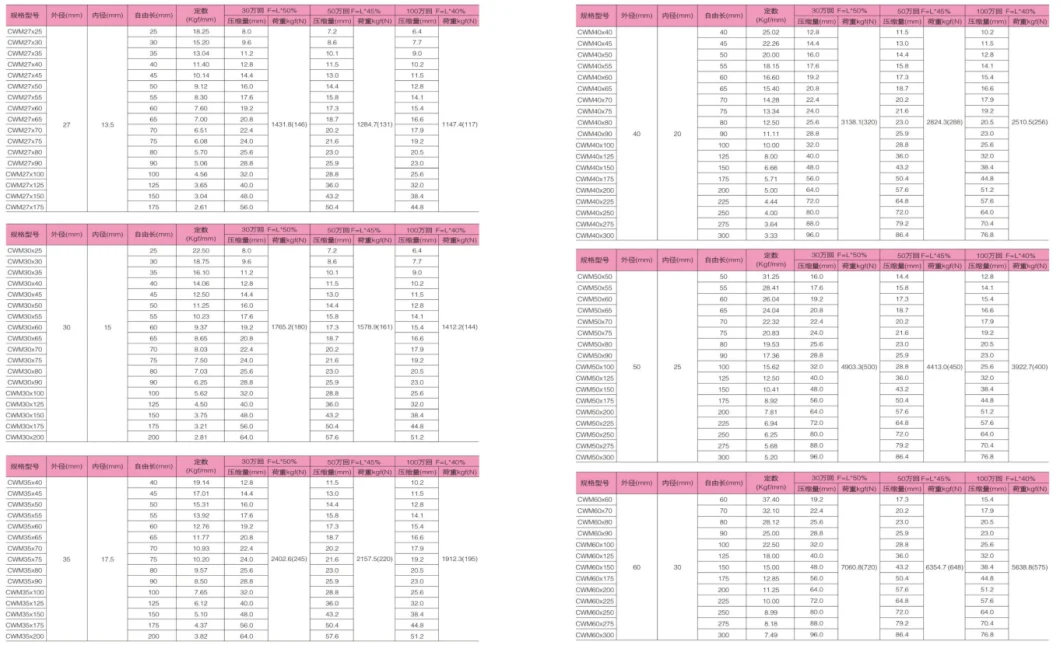

Molas de molde de compressão de alta precisão personalizadas, molas helicoidais Cungang Mold Parts é uma empresa que integra desenvolvimento, design, produção e vendas de kimonoA empresa moderna com serviços como um todo. Principais produtos: poste de guia de precisão GP, luva de guia GA/GB, conjunto de guia de esferas em miniatura, mola a gás de amônia. Conjunto de guia de esfera SRP/TRP, conjunto de guia deslizante SGP/TGP, conjunto de pilar de guia no molde do terminal A-TRP/T-TRP. Postes de guia independentes, componentes de guia de molde automotivo. Guias retas de alta qualidade para moldes de plástico e moldes de fundição sob pressãoColuna, luva guia (tronco métrico, tronco reto no tronco), ponto traseiro, coluna de suporte, SKD-61Dedal, dedal comum de 65mn, palete, luva de jito, tubo, inserção, pino de rosqueamento de pino sólido de precisão. T-pin cross pin, punch pin e outras peças de moldes heterossexuais, produçãoOs produtos são amplamente utilizados em moldes de estampagem de metal, moldes de fundição sob pressão, moldes de plástico, moldes de automóveis, equipamentos de automação mecânica, semicondutores, equipamentos médicos, aparelhos elétricos, eletrônicos e outros campos Vantagens do agente de vendas da empresa siderúrgica da vila: mola Datong, mola de molde de alta qualidade Guangben, mola retangular de molde doméstico. qualidade do produto,Estabelecido "alta reputação, alta qualidade, estoque suficiente e entrega precisa" entre os "grandes grupos de clientes em Guangzhou"Boa imagem corporativa. A empresa adere ao princípio de agir no interesse dos clientes do ponto de vista dos clientes, em linha com profissionalismo, qualidade, filosofia de atendimento a este negócio, de todo o coração, forneça aos clientes novos e antigos produtos melhores, mais serviço excelente.

|

|

|

|

|

|

|

How to use coil springs and precautionsUse when there is no spring guideIf the foreign object is clamped, the spring coil of the corresponding part will not be effective, as shown in Figure 1.When used without a spring guide, the spring will bend longitudinally and transversely, as shown, and cause other partial compression, which is actually equivalent to reducing the effectiveThe inner side of the bend will generate local high stresses, which will eventually break. Therefore, please be sure to use the number of spring coils, which will generate high stress and cause final breakage. So please be careful notSpring guides such as guide pins and outer diameter guides. Generally speaking, the guide pin isAllow foreign objects to enter. It is most ideal to use after passing through from top to bottom.Use in places with poor parallelism of the installation surfaceIf the inner diameter of the spring and the guide pin are poorly parallel to the mounting surface, the spring will bend horizontally, and the inner side of the bend is generated. It is recommended that the guide pin rod diameter be set to be about 1.0mm smaller than the inner diameter of the spring. If the gap between the guide pin and the guide pin is small, the guide pin will wear the inner diameter of the spring, and the wear part will be the starting point, causing local high stress, resulting in final breakage. In addition, as shown in Figure-4, when the parallelism of the mold is poor, the spring will be bent and the number of uses corresponding to the allowable compression amount will eventually be broken. And so on, leading to the ultimate loss. Please improve the parallelism of the mounting surface, and do not exceed the allowable. In addition, if the gap between the guide pin and the guide pin is too large, it will cause longitudinal bending. In addition, the use conditions such as the amount of compression. As shown in Figure 1, springs with longer free lengths (springs with free length/outer diameter=4 or more) must have a drop in the guide pin to avoid contact with the inner diameter of the spring when it is bent horizontally.Spring used in seriesAbout the outer diameter of the spring and the countersunk holeWhen used in series, as shown in Figure 5, the spring is bent and sometimes stuck on the guide pin or countersunk hole, and the same reason as causes the final breakage. In addition, due to the springIt is recommended that the diameter of the countersunk head be set to be about 1.5mm larger than the outer diameter of the spring. If the load is different from the counterbore, the spring with a smaller load cannot resist the spring with a larger load. When the gap is small, the outer diameter will expand due to the compression of the spring, and the outer diameter will be constrained, resulting in a small load The compression amount of the spring increases, resulting in reduced durability and breakage. The two form a stress concentration, resulting in a final breakage. It is ideal for springs with longer free lengths to adopt the counterbore shape shown in Figure 1. When springs are used in series, each spring constant value is halved.Springs are used in pairsWhen the guide length and the depth of the counterbore are smallIf the length of the guide is small, the spring will contact the front end of the guide when it is bent longitudinally. For example, when the springs are used in pairs, after the spring is bent longitudinally, the inside will enter between the outer wires (and vice versa) , And for the same reason as , it leads to the final friction and the final breakage. It is recommended to set the guide length to the initial setting height×1/2 to be damaged. In addition, a chamfering of approximately C3 size is performed.Horizontal use of wind springUse that exceeds the maximum compression (when used close to the compression length)When the spring is used horizontally, the guide pin will wear out the inner diameter of the spring, and start with the wear part.When used under the condition of exceeding the maximum compression, the cross section will produce high stress exceeding the calculated value.Points, leading to the ultimate loss. In addition, as the effective spring coil is gradually close to the compressed length, the spring constant increases, and the load line graph rises, which will generate high stress, resulting in final breakage. This is also the cause of deformation. Therefore, do not overwind the number of uses corresponding to the allowable compression amount for the use temperature. The load and other data described in the catalog are measured at room temperature (below 40°C). When the operating environment temperature exceeds room temperature, there will be differences due to various conditions, which may cause the load and durability times to decrease.Use without preloadThe ambient temperature for use should be below 80°C. Although the heat-resistant temperature of spring wire is higher than (round wireIf there is a gap, the spring will move up and down to generate an impact force, and will bend vertically and horizontally. If it is used after preloading, the top and bottom of the spring will become stable.120°C, rectangular 200°C) use temperature, but when used under conditions that exceed the use environment temperature, the function will be greatly reduced.